مع التوسع السريع للبنية التحتية العالمية لشحن السيارات الكهربائية، أصبحت المتانة طويلة الأمد عاملًا رئيسيًا يميز منتجات شحن التيار المستمر عالية الطاقة. في Workersbee،'نحن فخورون بالإعلان عن معيارنا الأوروبي موصل شحن DC 2.0 لقد نجح (200A) في اجتياز اختبار المتانة للتوصيل والفصل لمدة 30000 دورة بنجاح مع أداء حراري متميز، حتى في ظل الظروف البيئية القاسية.

يؤكد هذا الاختبار الذي أجرته جهة خارجية، والذي أجرته شركة Suzhou Sunchuang Energy Testing & Certification Co., Ltd.، أن Workersbee'موصل DC 2.0 ليس'لم يتم تصميمه فقط للأداء - إنه'تم بناؤه ليتحمل.

معيار جديد للمتانة في شحن التيار المستمر

لم تكن عملية الاختبار'ليس بالأمر السهل. على مدار أكثر من 40 يومًا، خضع منتجنا لما يلي:

30,000 دورة توصيل/فصل، بما في ذلك خطوات تلوث الملح والطين

خمس جولات من الضغط البيئي لمدة 24 ساعة عند -40 درجة مئوية إلى +85 درجة مئوية، ورطوبة 95%

مراقبة ارتفاع درجة الحرارة في الوقت الفعلي باستخدام كابلات التيار العالي مقاس 70 مم²

تحسين تصميم الاختبار المتوسط بإضافة فتحات لتبديد الحرارة بعد 24000 دورة

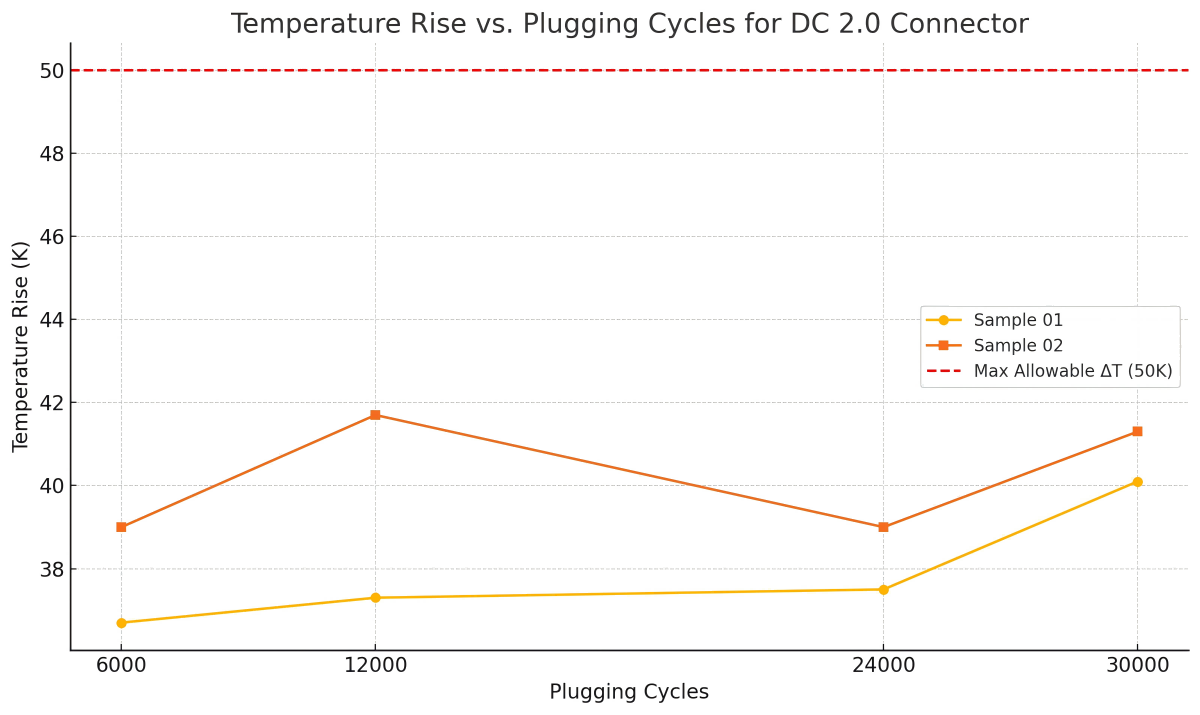

وعلى الرغم من هذه الظروف القاسية، فإن الموصل'لم يتجاوز ارتفاع درجة حرارة المحرك 50 كلفن، محققًا بذلك حدود السلامة الصناعية. وبلغ أعلى ارتفاع مسجل في درجة الحرارة 41.3 كلفن فقط عند 30,000 دورة، مما يثبت أداءً مستقرًا تحت الأحمال الثقيلة والاستخدام لفترات طويلة.

لماذا هذا مهم؟

بالنسبة لشركاء البنية التحتية للسيارات الكهربائية، تُترجم هذه النتيجة إلى موثوقية أعلى على المدى الطويل وانخفاض في تكاليف الصيانة. سواء كنت تُشغّل محطات شحن عامة أو تُزوّد مُصنّعي المعدات الأصلية بموصلات عالية الطاقة، فإن معرفة قدرة معداتك على تحمل 30,000 عملية دون تدهور تُعدّ ميزةً كبيرة.

"نُصمّم كل موصل في Workersbee مع مراعاة متانة المستقبل. نتيجة هذا الاختبار ليست مجرد شهادة، بل هي...'دليل حقيقي على التزامنا بالسلامة والمتانة والابتكار،” وقال مهندس كبير من فريق البحث والتطوير في Workersbee:

مُصمم للبيئات القاسية

الاختبار لم'ليس مجرد محاكاة للظروف المثالية. لقد طوّرنا المنتج ليتجاوز التوقعات التقليدية من خلال:

نقع الموصل في ماء مملح بالطين قبل اختبار الإدخال

تشغيلها خلال دورات المناخ القاسية

محاكاة الظروف الميدانية باستخدام كابلات شديدة التحمل مقاس 70 مم²

وهذا يجعل موصل DC 2.0 الخاص بنا مثاليًا للاستخدام في محطات الشحن العامة عالية الاستخدام، ومستودعات الحافلات، وأساطيل الخدمات اللوجستية، والمناطق ذات المناخ المتقلب.

Workersbee: قوة موثوقة وأداء مثبت

بصفتها إحدى الشركات الرائدة في الصين في تصنيع مكونات شحن السيارات الكهربائية، تواصل Workersbee التزامها بإنتاج منتجات تلبي المعايير الدولية وتتجاوز توقعات العملاء. يُعزز هذا الإنجاز محفظتنا من حلول الشحن عالية الطاقة المصممة لأوروبا وأمريكا الشمالية والشرق الأوسط وغيرها.

هل تريد معرفة المزيد عن موصل DC 2.0 الخاص بنا أو طلب عينة؟

اتصل بفريق المبيعات لدينا اليوم:

البريد الإلكتروني: info@workersbee.com

أهم النقاط:

تم اجتياز 30000 دورة توصيل دون أي عطل ميكانيكي أو حراري

ارتفاع درجة الحرارة أقل من 50 كلفن في جميع نقاط الاختبار

اجتاز اختبارات الحرارة الرطبة المتناوبة عند -40 درجة مئوية ~ +85 درجة مئوية / 95٪ رطوبة نسبية

تم التحقق منه باستخدام كابل 70 مم² للاستخدام بتيار عالي

يدعم التحسين الحراري المعياري مع غلاف مهوى